Marble cylindrical surface finishing process

Release time: 2017-07-24 Author: China Stone Network www.stone365.com

Marble finishes, cylindrical feel are often solid body. In fact, otherwise, in interior decoration works, sometimes need to play decorative role of marble surface column.

The structure of Dali stone column is angle steel and steel mesh skeleton, its operation process is: preparation of materials – production of cylindrical iron frame and fixed on the skeleton is brushed with antirust paint – welding wire mesh and wire in the online batch of cement mortar block base – install cylindrical stone Dali.

Preparation materials

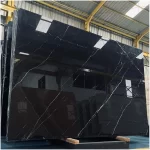

Material selection: it is very important to choose the same plate with the same color and pattern. When purchasing, the technicians should be strictly checked to ensure that the specifications, sizes, colors, patterns and materials of the board are good, so as to ensure the overall quality.

Processing and transportation: Marble processing should adopt advanced computer equipment for cutting, grinding, polishing, especially arc plate shaped stone, mosaic plate, and the Yang of the requirements of the project angle chamfering polishing technology, more computer processing, to ensure the processing precision, improve the processing quality. When transporting, it should be boxed to protect against damage during transportation, resulting in missing edges, falling corners and cracks.

Making skeleton

Primary treatment: before the installation, should be carefully verified according to drawing size structure and size, to exceed the allowable deviation of the cylinder will be revised, basic level to trim plate thickness not less than 5 cm. The base should have enough strength and rigidity, and the surface is smooth, and the dust, oil stain and residual mortar at the base should be removed. Horizontal release: after the base treatment, should play horizontal and sub line, pop-up column of the central line.

Skeleton installation, according to the specific location of the line. The skeleton is connected with the main structure by the connecting pieces. The joints are fixed to the main structure, usually with two fixed methods. One is the main structure of embedded iron, the connector with the iron weld. The other is to drill holes in the main structure and then connect the connections to the main structure with expansion bolts. The first method requires the embedment of the embedded iron pieces in the construction of the main structure. However, due to the error of civil construction and the influence of various artificial factors in civil construction, the size is difficult to control. Expansion bolts are often used in the construction site.

If the expansion bolt is used, the embedded depth of the expansion bolt shall be guaranteed. Because the drawing force of the expansion bolt is related to the embedded depth. In this way, the impact drill is required to drill at the required depth when drilling on the concrete structure. When the reinforcement is encountered, it should be staggered. But should be fixed in a strong position. When the connecting piece is fixed, the framework can be installed. The vertical bar member is usually installed, because the vertical member is connected with the main structure, and when the vertical member is in place, the transverse bar member can be installed. If they are members of a class of steel material, can be used in welding, also can use bolts or other connection.

Skeleton installation, attention should be paid to the skeleton itself. Most of the steel frames we use are painted with antirust paint, and the number should be in line with the design requirements. The skeleton is installed should conduct a comprehensive inspection, especially the center line anyway bar, note: interval size should be horizontal keel and slate material of the same height, in order to set the steel wire or stainless steel wire for binding of marble.

Welded wire mesh

Steel mesh cement mortar base surface of the skeleton, can be used for coarse wire grid is 20-25 mm 16-18, steel wire mesh or galvanized wire mesh. The wire network can not be directly welded with angle iron framework, but the first in the number 8 on the surface of the angle iron framework welding around the wire, and then the wire mesh is welded on the 8 wire. The whole wire mesh must be welded and welded properly with the Dragon skeleton.

After the welding is finished, a steel wire is bound on the transverse keel of each layer, and the steel wire extends out of the steel wire net. The amount of lashing steel wire should be determined according to the number of stone surface. Generally, a steel wire is needed for a piece of surface. If the stone surface size is less than 100 mm * 250 mm, it can also be tied without steel wire.

Batch cement mortar

Mix 500 cement with medium sand to form cement mortar. The mixture ratio is 1:2.5, and a little fiber can be added to the cement mortar to increase the performance of the cement mortar. When mixing, the water consumption should be controlled so as to make the cement mortar have a certain consistency.

Number of cylindrical block of cement mortar, from the top down, in turn. Batch embedding requires grout to be embedded in the mesh of the wire mesh. Number of hanging uniform thickness, large flat surface, but not smooth plaster group. When the batch is wiped, the steel wire that is tied on the transverse keel should also be thrown out.

The marble surface of a column is inlaid with paste

The cylindrical surface covered with marble with a diameter equal to the wooden splint od column template, to determine the size of slab cutting angle by profiling. The method is as follows: first in the master side by direction to put a few blocks veneer stone plate, stone on the measurement required cutting angle angle. Then according to the angle in the stone cutting machine cutting angle, cutting angle of the stone plate will be placed in profiling side, observation of two stone plate butt, if it can be on, according to the angle of corner cutting processing.

When the base circle inlaid by profiling as a cylindrical mounting. The first position is fixed on the profiling of the column below, and then from the start with a layer of cylinder paste, to gradually covered with stone veneer, inlay stone plate cylindrical structure as shown below:

To start the installation, according to the number of stone and straight wire net eraser, portable stone in place, according to the horizontal and vertical lines to find, in the next two leveling, pull a line from the smallest angle, right behind the slate slate into the mouth under the wire bound on the transverse bar, do not tight binding, the copper wire and horizontal bars can be fastened, and then lashing stone plate is copper, and with a wooden wedge pad. By the ruler to check and adjust the wedge, then fasten the wire. Proceed to the other side in turn. Install each piece of stone, such as the discovery of specifications are not allowed or stone plate gap stone plate uneven application of lead leather pad, the stone plate gap is uniform, in order to maintain the first layer of slate is flat, second storey stone installation foundation, in turn, until the completion of the overall.