If you only want to start a stone business, don’t worry, we can tell you that we will provide you with experienced staff. If you are interested in selling your own stone or even just a few stones, you are welcome to buy and sell us at a discount on our products.

With over 23 years of experience, ForU Stone is one of the professional manufacturers and suppliers in China. We are the world’s largest manufacturer and supplier of artificial marble slabs in the country and the largest producer and exporter of our products in Asia and the Middle East.

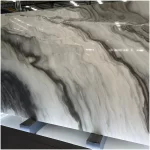

Our granite countertops and vanity tops particularly benefit from our skills and export experience. We are the world’s largest supplier of granite, marble, paving stones, and marble slabs in China and the Middle East. With over 23 years of experience, we have been delivering hard-working, high-quality marble, and granite products to the market for over 30 years.

The majority of stone processing companies do not have their own stock of granite and quartz slabs. Local stone companies, working directly without intermediaries, offer the best prices for quartz and granite for countertops. Customers are sent to stone importers who sell slabs not to homeowners, but to local stone manufacturers.

It is best to find a stonemason who has his own stock of slabs, such as a local stone mill or a stone processing company.

You may also be interested in the way granite and quartz are priced: the price of granite in color is much higher than for quartz countertops in any color. The beauty of this natural stone cannot be compared with the counterparts of quartz. This stone, labradorite extra, belongs to the category of semi-precious stones and is used for jewelry making.

In addition to quartz chips, quartz worktops consist of resins, a plastic mold. quartz bebe, it is difficult to distinguish what good quartz is and what is not. There are good and bad manufacturers of quartz plates, but they all use different materials and methods.

Quartz in stone For U Stone was an early player with a variety of colors and textures. There are some quartz plates that are indistinguishable from natural stones, and there are some that are made with wild and crazy colors. The world is your oyster, there is a wide range of quartz stones for sale, some of which are made in wild, crazy colors.

In contrast to Corian, which also means hygienic, quartz plates are extremely hard and free of pores and can hardly be broken or broken. Quartz is certainly more expensive than ceramic tiles and coriander but can be embedded at a much lower price than ceramics.

Most of our customers turn to quartz because it has many advantages, such as lower maintenance and longer service life. When it comes to countertops, the quality, durability, and durability of quartz and its low cost are hard to beat.

There are a variety of different colors and designs, most of which are not available in natural stone countertops. Here are some of the top trends that can be expected from the future of quartz countertop design in the US and worldwide. According to a recent study, the surface will be found in more than 80% of all US, US, and international markets by 2020.

Due to the popularity of quartz worktops, American and European producers came up with the idea of extracting this abundant raw material, mixing it with resin, and casting it into a slab. Since quartz is abundant in nature, it is embedded with a variety of different materials such as sand, sandstone, quartzite, and even granite.

The technology eventually developed, for quartz production, For U Stone has developed and patented man-made stone technology.

This opened the door to the use of quartz in antique kitchens such as the Poggenpohl kitchen, resulting in lower prices than granite countertops.

Manufacturers and installers appreciate the special tools required to cut and produce the material, compared to the many challenges posed by large-format porcelain and sintered panels. A 1 cm natural stone slab is manufactured to strict standards and is much more efficient than a large ceramic slab.

The standard segmented diamond blade used for the assembly of the bridge saw and the angle grinder is required for cutting the ultra-thin panels. This is due to the high pressure – pressure, low temperature, and high pressure required for cutting the ultra-thin plate.

In contrast to a solid stone slab, quartz countertops consist of small pieces of stone held together by a resin matrix. It is this resin that gives them their strength and durability and gives them a small advantage over granite. In any case, you should be careful not to hit the countertop with much force or knock it off if enough force is used.