What is stone block?

-

Subject content and scope of application

This standard specifies the product classification, technical requirements, test methods, inspection rules, signs, transportation, storage, etc. of marble blocks (hereinafter referred to as blocks).

This standard applies to blocks and other building materials used in the processing of building veneer materials from marble ore bodies.

2, reference standards

GB 9966.1 Test method for natural facing stone – Test method for compressive strength after drying, water saturation, freeze-thaw cycles

GB 9966.2 Test method for natural facing stone Test method for bending strength?

GB 9966.3 Natural facing stone test method Bulk density, true density, true porosity, water absorption test method?

3. Product classification?

3.1 Classification?

3.1.1 According to the shaping method, the blocks are divided into two categories:

a. saw surface block (SS): six faces are cut by the sawing method.

b. Kneading material (CS): One or several sides are blocks that are shaped by chiseling.

3.1.2 According to the volume, the blocks are divided into three categories (Table 1).

Category

I

II

III

Volume

≥3

≥1~<3

≥0.35~<1

3.2 grade?

According to the size of the block, the tolerance, the flatness allowable limit tolerance, the angle allowable limit tolerance and the appearance quality are divided into two grades: first grade (B) and good grade (C).

3.3 naming and marking?

3.3.1 Block naming order: name of the place where the material is produced, name of the tone pattern, marble (M).

3.3.2 Block marking sequence: naming classification, size, grade, standard number.

3.3.3 Marking example:

The first-class white block material produced by Fangshan in Beijing, the size of the specification is 250cm × 150cm × 100cm?

Fangshanbai (M)CS 250×150×100 B JC202?

4. Technical requirements?

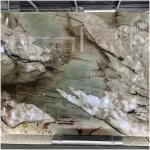

4.1 Blocks must have the shape of a right-angled parallelepiped, the names of which are shown in Figure 1.

4.2 The size of the block material should meet the requirements of (Table 2).

Part

Length

Width

Height

Size

≥100

≥50

≥70

4.3 The length, width and height dimensions of the blocks allow extreme tolerances, flatness and angle tolerances to be met in accordance with (Table 3).

Indicator

Name saw surface block

Noodles

Class I, Class II volume

Class III Volume I, Class II Volume

Class III volume

First-class products, first-class products, first-class products, first-class products, qualified products, first-class products, qualified products

Height 3

5 2 4 5 6 4 5

Length,

Width 6 5 6 10 5 9

Flatness 2 3 2 3 3 5 3 5

Angle 5 5 4 7 4 7

4.4 Appearance quality?

4.4.1 The tone pattern of the same batch of blocks should be basically the same. ?

4.4.2 Appearance quality grades such as missing corners, missing edges and cracks of the blocks shall comply with the requirements of (Table 4).

Content

Class I volume Class II volume Class III volume

First-class products, qualified products, first-class products, qualified products, first-class products, qualified products

Notch length 10-30cm, width 3~8cm, depth: 3~5cm 0 1 0 1 0 1

Lack of edge length ≤10cm, width, depth 3~5cm 3 4 2 3 1 2

The top surface and the end surface of the crack are substantially parallel to the large surface, and the length is <50cm 1 2 1 2 1 2

Number of allowed on the large surface 0

Weathered, hard minerals that affect processing

4.5 Physical properties?

4.5.1 The bulk density is not less than 2.60 g/cm.

4.5.2 Water absorption rate is not more than 0.75%.

4.5.3 The dry compressive strength is not less than 20.0 MPa.

4.5.4 The bending strength is not less than 7.0 MPa.

5 test methods

5.1 very poor size

The maximum and minimum dimensions of the length, width and height of the block were measured with a steel tape measure with a scale tolerance of 1 mm. The difference between the maximum size and the minimum size is used to indicate the difference in length, width, and height. The reading is accurate to 1 cm.

5.2 flatness

A steel flat ruler with a straightness tolerance of 0.1 mm and a length of 1 m is placed on the plane to be inspected, and a steel tape measure is used to measure the maximum gap between the ruler and the plane. The maximum measured value in each face is used to represent the plane limit tolerance of the block. The reading is accurate to 1 cm.

5.3 angle

The internal angle perpendicularity tolerance is 0.13mm. The 90 steel square with an inner corner of 45 cm × 40 cm measures the angle between adjacent faces of the block. Take a flat surface of the block material as the reference surface, and press the side of the square to the reference surface. Use a steel tape measure to measure the gap between the other side of the square and the measured surface. When the measured angle is greater than 90, the measuring point is at the root of the square; when the detected angle is less than 90C, the measuring point is 40cm from the root. The maximum measured value in each angle is used to represent the angular limit tolerance of the block. The reading is accurate to 1 cm.

5.4 Appearance quality?

5.4.1 Color pattern, weathering, hard mineral visual inspection.

5.4.2 Notched, ribbed, measured with a steel tape measure, the length, width and depth of the missing edge.

5.4.3 Cracks are determined by visual inspection, hydroponic method (observation of water penetration) or hammering method (strike with a metal hammer, if necessary, to block the sound of the block) and determine whether the crack exists. The length of the crack in the direction of the extension was measured with a steel tape measure.

5.5 Physical properties?

5.5.1 Bulk density and water absorption rate shall be in accordance with the provisions of GB9966.3.

5.5.2 Dry compression strength shall be carried out in accordance with the provisions of GB9966.1.

5.5.3 Bending strength shall be in accordance with the provisions of GB9966.2.

5.6 Acceptance volume is calculated using the minimum size of the block.

The 5.7 size is indicated by the minimum size of the block.

6 inspection rules?

6.1 Mining inspection?

6.1.1 Inspection items: very poor size, flatness, angle, appearance quality

6.1.2 Group batch: The same color pattern, category, grade of block material is 5m as a batch. Less than 5m can be counted in batches. ?

6.1.3 Inspection: The same batch of blocks are tested block by block.

6.1.4 Judgment: If all the test results meet the corresponding quality level in the technical requirements, it is determined that the batch of materials meets the quality level; if one item does not meet, it is determined that the batch of materials does not meet the quality level.

6.2 type test

6.2.1 Inspection items: All items in the technical requirements.

6.2.2 Type inspection is carried out in one of the following cases:

a. When the new mine is put into production;

b. When there are obvious variations in the color tone and pattern of the ore body;

c. Every two years during normal production;

d. When the national quality supervision agency proposes the type inspection requirements.

6.2.3 Group batch: same as the mining inspection.

6.2.4 Inspection: The dimensions are extremely poor, flatness, angle, and appearance quality are tested block by block. The physical properties were randomly sampled from different blocks in the batch of materials and tested according to the provisions of GB9966.1-9966.3.

6.2.5 Judgment: If one of the test results of physical properties does not meet the requirements of 4.5.1-4.5.4, it is determined that the batch of materials is a non-conforming product. The test results of other projects are the same as the mining test.

7 signs, transportation and storage

7.1 mark

Mark the block with the non-washable pigment on both ends of each block.

7.2 Transportation

The blocks are protected from impact during transportation and loading and unloading.

7.3 Storage

When the blocks are stored, the classification and classification codes are stable. Prevent pollution.

7.4 Delivery

The blocks are delivered at the mine and a quality certificate should be submitted at the time of delivery.