What are semi precious stones

Semi-precious stones are loved for their extremely rare and precious materials, colorful colors, unpredictable textures, eclectic patterns, and crystal clear luster.

Today, as stone decoration is becoming more and more popular, high-end decoration has higher and higher requirements for stone materials. For the decoration of celebrity clubs and luxurious rooms, precious semi-precious stones are more popular, so that the interior decoration presents an extravagant and luxurious effect.

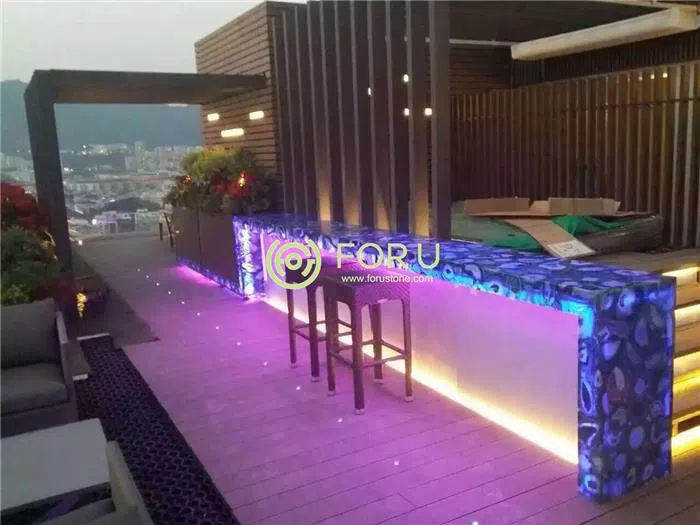

Semi-precious stones already look very luxurious, coupled with various innovative designs, such as lighting, large board splicing, water knife mosaic and other designs, it will add a layer of luxury to its luxury.

Semi-precious stones, like other luxury stones, can be applied to the background wall of the interior space, the wall floor of the living room, the island in the kitchen, the countertop of the sink, etc. It is also involved in the decoration of furniture desktops and hanging pictures.

The pasting process of semi-precious stones is very complicated. A large slab of pure natural semi-precious stones is hand-assembled after fine layout by experienced craftsmen, which can show the luxury of semi-precious stones.

Processing of semi-precious stone slabs:

Semi-precious stone slabs are composed of natural gemstones and minerals. In nature, these semi-precious stone minerals usually exist in the form of small pieces, while the whole semi-precious stone slab is hand-selected by craftsmen and spliced together piece by piece. ,

Processing of semi-precious stone slabs: semi-precious stone slabs are composed of natural gemstones and minerals. In nature, these semi-precious stone minerals usually exist in the form of small pieces, while the whole semi-precious stone slabs are manually selected by craftsmen. Formed by bonding them together with epoxy resin, the resulting panels are each unique. Although the epoxy resin provides some additional bending strength to the formed slab, the processing of the semi-precious stone slab is still very demanding on the workmanship

When cutting semi-precious stone slabs, you need to buy special cutting discs. The polishing of the edges can be performed the same as other standard granites, and the processing speed of the machine must be reduced by half. For manual polishing, water polishing must be used, because our Semi-precious stones have minerals throughout the slab.

Ammonia, bleach, or any other harsh cleaning agents must be avoided when cleaning semi-precious stones. Mild or neutral detergents are suitable for cleaning the surface of semi-precious stones. When storing stone slabs, avoid direct sunlight and avoid placing stone slabs at temperatures below 10°C (50°F) or above 40°C (104°F). Down.

Installation requirements:

Generally, the distance between the support points of the 30mm thick semi-precious stone slab should not exceed 60 cm, and the span between the slabs should be reduced to a minimum to prevent damage and cracking. For the countertop, the distance between the fulcrums shall not exceed 30 cm.

In the case of suspension, the support points must be firm, and if the distance between the support points exceeds the maximum value mentioned above, additional support and fixing need to be strengthened.

The standard size of common agate semi-precious stone slabs is 1450x 2750 x 30mm, so when installing semi-precious stones on the countertop, you should pay attention to:

Generally, the distance between the support points of the 30mm thick agate semi-precious stone slab should not exceed 60 cm, and the span between the slabs should be reduced to a minimum to prevent damage and cracking.

And because agate semi-precious stones are formed by combining semi-precious stones with epoxy resin, it is not resistant to high temperature, so although it can be installed on the ground as a floor, it cannot be equipped with floor heating. At the same time, its installation area must avoid generating High heat, such as installed on the kitchen countertop, hot pot and other kitchen utensils higher than 40 ℃, must be separated by heat insulation pads to ensure that the semi-precious stone countertop will not be damaged.

New products in the semi-precious stone series:

Traditional semi-precious stone processing uses a single semi-precious stone block, combined with epoxy resin glue to calibrate and polish to form a whole stone board, but with the advancement of technology, the semi-precious stone series also ushers in its “semi-precious stone with more excellent characteristics”. New product”.

This new product also adds amethyst, very pure quartz, including petrified wood, in the process of processing. The fusion of diversified materials makes the new semi-precious stones have more prominent physical properties. The products in this series can even be colored Reflective, unique brightness, light transmission and other characteristics

Related Products