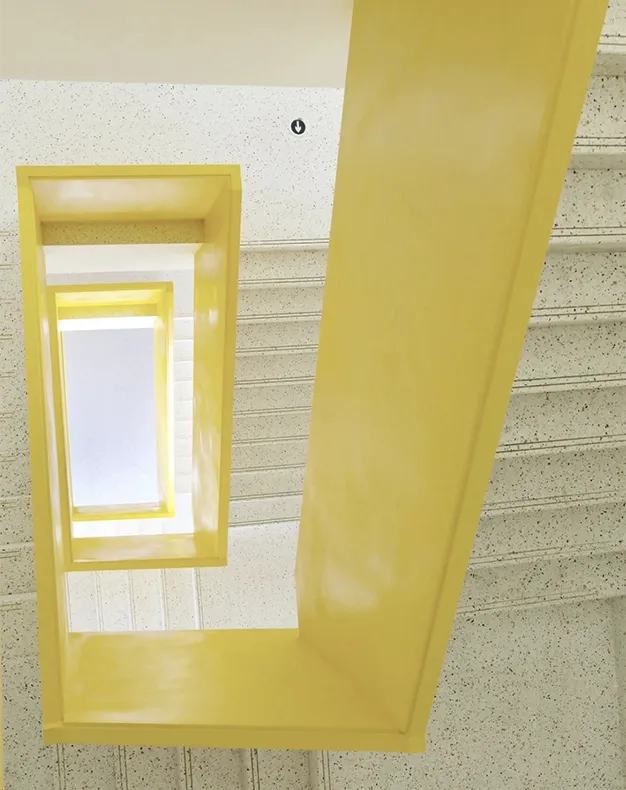

Precast

Terrazzo Stone Factory

Offers a comprehensive range of over 50 high-quality precast terrazzo stone collections, each with a unique blend of rich colors and intricate patterns. With High colors and pattern customized designs, FOR U STPONE’s Terrazzo Stone Slabs are suitable for a wide range of applications, including the exterior and exterior floor, wall, and Countertop decoration of municipal halls, hotels, shopping malls, and other real estate projects.

Inorganic Terrazzo

Born of art, craving for beauty

The intricate combination of various materials, colors, and textures in inorganic terrazzo stone art parquet provides a wealth of decorative inspiration. This versatile building decoration man-made stone material is suitable for a range of projects, including hotels, malls, office buildings, cafes, restaurants, bakeries, resorts clothing and beauty boutiques, kitchens and bathrooms in private residences, creative spaces, concept stores, and more. It can be used in both partial and large areas to enhance the overall aesthetic of a space.

Advantages

Precast Terrazzo Stone

- Resource Efficiency: The utilization of recycled materials and advanced manufacturing techniques results in reduced waste and an improved utilization rate of resources.

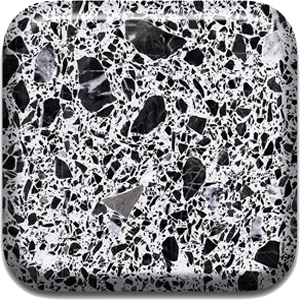

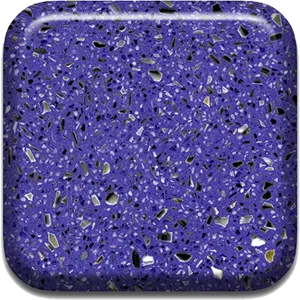

- Vibrant Color Palette: The incorporation of a diverse range of aggregates allows for the creation of personalized products with a rich color selection.

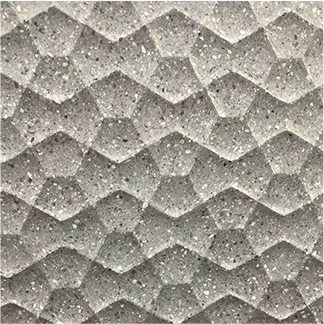

- Versatile Surface Textures: The production of a range of classic surface effects, such as matte, litchi, antique, and brushed, as well as the capability for customization, provides limitless creative possibilities.

- High Capacity and Consistency: The use of vacuum pressing and industrialized mass production results in stable quality and uniform color, while standardized processing ensures efficiency.

- Cost-Effective: Tailored solutions to meet customer needs help to ensure quality and minimize costs.

- Environmentally Friendly and Safe: The absence of resin, toxicity, smoke, and radioactivity, as well as its fire-retardant properties, make inorganic terrazzo a safe and environmentally conscious choice.

- Outstanding Performance: With features such as anti-slip, wear resistance, corrosion resistance, freeze-thaw resistance, versatility in shaping, ease of installation, low maintenance, and decorative appeal, inorganic terrazzo exhibits superior performance in a variety of applications.

Recommendation colors

Terrazzo Floor And Wall

high customized | Oem Service

Precast Terrazzo Stone In Colors, and Chips Sizes To Meet Different Commercial Building, Schools, And Malls

Inorganic Precast Terrazzo tiles, with their highly customizable color and particle size options, are dedicated to serving the modern and environmentally conscious green space. We continuously explore new technologies and techniques to research and develop materials that are suitable for green buildings, commercial real estate, public educational institutions, and other indoor and outdoor decoration projects. Our mission is to create a unique and healthy space, free from odor and pollution, with a focus on artistic and aesthetic values. Let us help bring to life the unique charm of your space through our innovative materials and design concepts.

Specifications| Applications

Floor/Wall Covering Tiles Of Terrazzo Stone

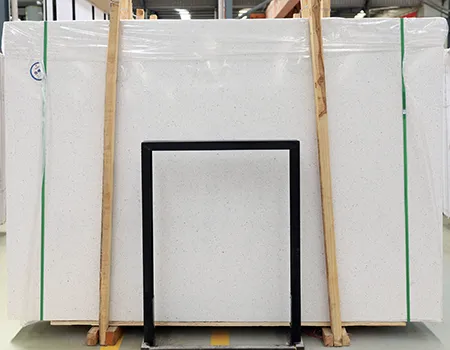

- Regular Jumbo Slab Sizes:

1600mm x 2400mm, 1600mm x 3200mm, 1800mm x 2700mm.

- Cut-to-Size Project Tiles of Terrazzo Stone:

600mm x 600mm, 800mm x 800mm, 600mm x 1200mm.

Thickness: Customizable to meet specific requirements.

- Application Areas of Terrazzo Stone:

-Indoor and Outdoor Covering Tiles: Ideal for use in hospitals, schools, theaters, exhibition halls, hotels, offices, specialty stores, restaurants, shopping malls, subways, stations, airports, and other public spaces for wall, floor, and countertop paving.

-Exterior Walls: Suitable for dry hanging on building exterior walls, as well as for paving in courtyards and walls.

-Custom Shaped Decorations: Ideal for creating lines, Roman columns, fireplaces, countertops, artwork, ornaments, and other decorative elements to meet custom design needs.

Main colors of terrazzo

popular with real estate developers, residential designers and construction companies

Eco-Friendly Excellence The Signature of Inorganic Terrazzo

At the heart of our inorganic terrazzo stone lies a commitment to natural, green, and healthy materials that prioritize environmental friendliness. This philosophy of ecological sustainability sets us apart and makes our products the preferred choice for those seeking a harmonious balance between design and the environment.

What is Precast Inorganic Terrazzo

Interior and Exterior Decoration Stone For Buildings

Inorganic terrazzo, also known as cement-based terrazzo, is a composite building material created by combining silicate cement with natural fine-grained stone aggregates. The mixture is applied to surfaces, solidified, and polished to a smooth finish.

Inorganic precast terrazzo slabs or tiles are produced using the latest technology from Italy. The process involves the polymerization of natural stone waste, broken glass, shells, and other aggregates under high pressure and high-frequency vibration. This creates a recyclable and environmentally friendly building material that is safe, healthy and has physical properties comparable to natural stone. The inorganic terrazzo also boasts fire-retardant properties, resistance to acid and alkali weathering, and is suitable for both indoor and outdoor use, making it a versatile and innovative choice for construction projects.

Expert Precast Terrazzo Manufacturing

FOR U STONE specializes in building precast terrazzo products for institutional, commercial, and industrial projects. With the ability to manufacture a wide range of terrazzo products, we bring versatility and customization to your project.

Versatile Terrazzo Options: Cove Wall Base, Straight Wall Base, Countertops and Bar Tops, Wall Panels, Column Covers, Stair Treads, Stair Treads and Riser Combinations, Stair Landings, and Windowsills.

Countertops | project tiles

Majestic Nature / Magical Terrazzo

Terrazzo Installation Guidelines

Terrazzo Stone Tiles A Fine Choice for High-Class and Art

“Sealant Protection Before Shipment”

Before shipment, it is crucial to protect the terrazzo on all six sides with a sealant, such as Sikang KY40, and to coat the bottom surface with Sikang KY50 sealant for added protection.

“Ideal Construction Temperature”

For optimal results, the ideal construction temperature is within the range of 5-35℃. If the temperature is outside of this range, appropriate insulation measures should be taken or construction should be stopped if the temperature is below 0℃ or above 40℃.

“Gap and Expansion Joint Considerations”

A gap of 1.5-2.0mm should be left between each terrazzo piece, and for large-area paving, expansion joints should be reserved every 8-10 meters in both vertical and horizontal directions.

“Quality Inspection”

For every 30 pieces of terrazzo paving, one piece should be opened for quality inspection to ensure that the bonding area between the adhesive, terrazzo, and leveling layer is at least 95%.

“Adhesive Usage”

It is important to use the adhesive within its specified use time (2 hours at 21°C) and to avoid diluting the two-component emulsion with water. Any unused material or skin filming should not be used.

“Splicing Protective Cushion”

After construction, it is necessary to splice the finished protective cushion into a single piece to prevent cement and sand particles from falling onto the surface of the terrazzo through any gaps and causing pollution.

“Post-Construction Precautions”

Pedestrian traffic should be avoided for the first 3 days after the paving construction is completed, and heavy equipment, cargo handling, and ladder erection should be strictly prohibited for 7 days.