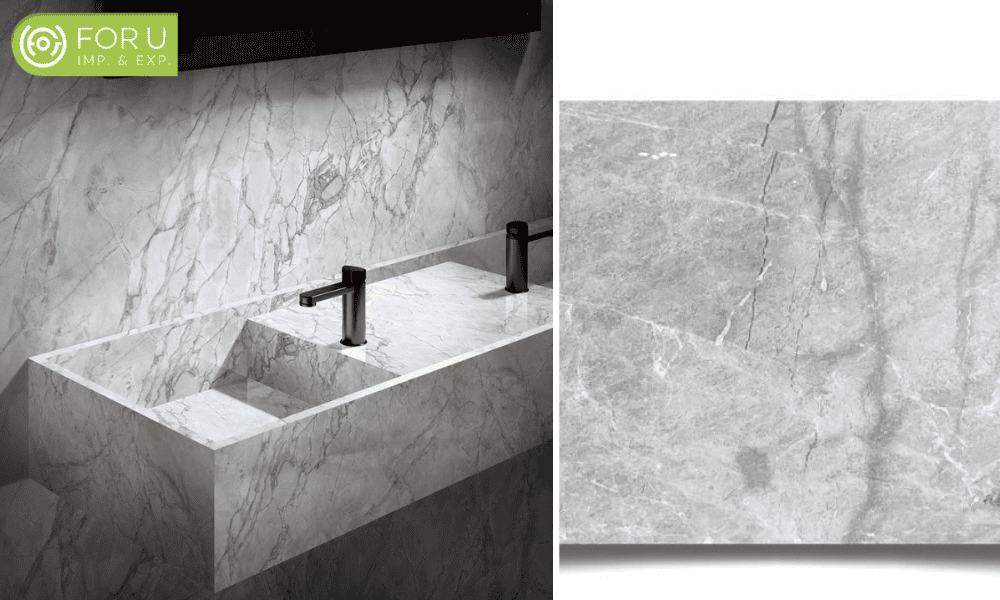

Marble has been the material of choice for architects and artisans for more than two millennia, prized for its quiet luxury and enduring performance. Among the many colour families, Grey Marble Slabs occupy a special niche.

Their neutral palette harmonises easily with modern minimalism, post‑industrial lofts, and classical interiors alike, while the subtle veining brings movement to flat planes. For designers searching for calm sophistication and contractors who need predictable mechanical strength, the grey spectrum offers a sweet spot between pure‑white statuario and dramatic nero marquina.

Yet beauty is only part of the equation. Today’s decision‑makers must also balance environmental compliance, transparent pricing, and resilient supply chains. China’s 2024‑2025 “green mine” directive broadens ecological requirements to all quarries, accelerating the industry’s shift toward energy‑efficient cutting and closed‑loop water systems.

The Geology and Aesthetic Spectrum of Grey Marble

Geological Origins

Most commercial grey marbles originate in tectonically active limestone belts where magnesium‑rich fluids recrystallise calcite into denser, fine‑grained mosaics. The resulting matrix accepts a mirror polish, yet retains enough micro‑fissures to showcase delicate white, silver, or charcoal veining. Classic varieties—such as Guanxi Grey, Tundra Grey, and Bardiglio—carry between 95‑98 % calcium carbonate, giving them a 3‑4 Mohs hardness that polishes to 90‑plus gloss units.

Chromatic Nuance

A single block can move from pearl to pewter within one diagonal metre, allowing fabricators to book‑match dramatic waterfall islands or lay large‑format tiles in a near‑solid tone. Titanium dioxide yields cool, steely undertones, while traces of hematite introduce warmer greige notes. This tonal agility is one reason Grey Marble Slabs have overtaken white marbles in hotel‑lobby refurbishments since 2023.

Global Demand and 2025 Market Trends

Macro Drivers

Residential Retrofits: Post‑pandemic renovation surges in North America and Europe continue to favour tactile, natural finishes over synthetic quartz.

Commercial Resilience: Big‑box retail is repurposing footprints into mixed‑use “lifestyle centers” that demand durable yet refined floor systems.

Colour Psychology: Grey’s association with calmness pairs with biophilic design, which is now a baseline requirement in Class‑A offices.

Trade Flows

China remains the world’s largest processed‑marble exporter by square metre, thanks to coast‑adjacent industrial clusters in Fujian and Shandong. East‑bound logistics average 22 days to Los Angeles and 28 days to Rotterdam, versus 45‑plus days ex‑Mediterranean. Forustone’s Xiamen hub alone can load four 20‑ft containers per cutting line per day, ensuring schedule certainty even during seasonal peaks.

Compliance and Sustainability

China’s “Green Mine” Framework

In April 2024, a seven‑ministry circular mandated that 90 % of large‑scale quarries meet green‑mine metrics—dust suppression, progressive backfilling, and energy‑intelligent sawing—by 2028. Third‑party certification fees are now government‑funded, removing cost barriers for compliance.

Forustone’s Workflow

At our Longyan quarry, photovoltaic arrays feed 37 % of annual electricity, while closed‑loop slurry presses reclaim 92 % of cutting water. Waste rock is crushed into road‑base aggregates, converting a disposal item into revenue. These measures keep embodied‑carbon scores under 160 kg CO₂‑eq per m²—well below the 2025 EU Taxonomy threshold for architectural stone.

Documentation

For every batch of Grey Marble Slabs, Forustone issues:

Digital quarry‑of‑origin certificate (ISO 14067 compliant)

Radiation test (GB6566 Class A)

Resin‑content disclosure (≤ 0.6 %)

Pricing Structure and Cost Drivers

Benchmark Numbers

Public marketplaces list Chinese tundra‑grey slabs between USD 27 and USD 100 per square metre FOB Xiamen, depending on grade and size. Entry‑level vein‑cut material at 2400 × 1400 × 18 mm with ≥ 20 m² yield sits at the lower bound. Boutique Hermes‑Grey blocks, trimmed to 2000 × 1200 × 20 mm with less than 2 % calcite clouds, command the upper tier.

Hidden Variables

Block Recovery Rate – A quarry with 83 % recovery can shave USD 4–6 off the grey marble price per sqm compared with a 70 % site.

Slab Thickness – Moving from 18 mm to 20 mm raises raw stone consumption 11 % but lifts bending strength 15 %.

Finish Complexity – Leathered or volcano‑brushed textures add 2–3 linear passes on CNC machines, costing an extra USD 4 per m².

Currency Volatility – A 1 % RMB appreciation currently shifts FOB prices ~USD 0.35 per m².

2025 Outlook

Freight‑rate stability has returned after the 2024 Red Sea rerouting premium. Barring force majeure, analysts project the grey marble price per sqm band will stay within USD 30–110 through Q4 2025.

Inside a Grey Marble Factory China: Quality Control to Dispatch

Block Reception

Each arriving block is drone‑scanned for volume; AI algorithms predict optimum cut orientation to minimise waste and align veining.

Slabbing and Curing

Gang‑saws slice 40 blocks in parallel with diamond wires cooled by recycled water.

Resin infusion fills micro‑voids, followed by 12‑hour kiln curing at 60 °C for structural integrity without colour shift.

Final Inspection

A multi‑camera conveyor captures 8K images at 0.2 mm resolution; software flags quartz pockets or dominant fissures exceeding 1:10 length‑width ratio. Human inspectors then grade A, Commercial, or Utility. Only A‑grade joins the export queue.

Selecting a Grey Marble Slabs Supplier China

Due‑Diligence Checklist

License & Green‑Mine Status: Request digital certificates issued post‑2024 circular.

Capacity Alignment: Can the supplier guarantee ≥ 500 m² of consistent tonality from the same lot?

Traceability: Look for QR codes etched on slab edges linking to batch documentation.

Third‑Party Audits: SGS or TÜV site reports under 12 months old.

Negotiation Tactics

Agree on a rolling‑hold deposit with visual inspection at 30 % production milestone.

Embed a colour‑variation tolerance clause (e.g., ΔE ≤ 1.2 under D65) into the proforma.

For high‑variation stones, secure the originating block inventory upfront to avoid mid‑project mismatch.

Design Applications and Case Studies

Luxury Residences

In a Suzhou lake‑front villa, 20 mm book‑matched Grey Marble Slabs form a seamless kitchen island cascading into a cantilevered breakfast bar. The calm grey veining contrasts walnut cabinetry and brushed‑gold fixtures, adding quiet opulence.

Hospitality Lobbies

A Bangkok five‑star hotel replaced ageing limestone with leathered Grey Marble Slabs across a 1,200 m² lobby floor. The non‑directional texture disguises grout lines, while the medium‑dark tone masks trolley scuffs, reducing maintenance overhead by 18 % year‑on‑year.

Retail & F&B

For a flagship fashion store in Seoul, ultra‑thin 12 mm composite Grey Marble Slabs were laminated onto honeycomb aluminium panels, delivering the marble look at 40 % weight savings—critical for upper‑floor load limits.

Care, Maintenance, and Life‑Cycle Value

Daily Upkeep

pH‑neutral detergents suffice; avoid citrus‑based cleaners that can etch carbonate surfaces. A quarterly buff restores the low‑gloss “silk” finish of honed slabs.

Sealing Cadence

For kitchens, solvent‑borne penetrating sealers should be reapplied every 24 months. For high‑traffic lobbies, intervals shorten to 12 months, especially on leathered textures that carry micro‑pits.

Repair Pathways

Chips < 10 mm can be in‑filled with colour‑matched epoxy. Cracks along natural fissure lines respond well to butterfly‑key reinforcement, returning 80‑90 % of original bending strength.

Grey Marble Slabs sit at the intersection of aesthetic versatility, structural endurance, and—thanks to forward‑looking policy—improved eco‑performance. China’s 2024‑2025 green‑mine standards sharpened industry focus on closed‑loop water, renewable energy, and transparent certification, helping specifiers meet tightening global ESG benchmarks without sacrificing design ambition. Market data show a stable grey marble price per sqm range, giving budget predictability even as freight surcharges normalise.

Selecting the right partner remains pivotal. A top‑tier grey marble slabs supplier china couples quarry ownership with a rigorously audited grey marble factory china, ensuring colour continuity, timely dispatch, and after‑sales technical support. Forustone embodies that vertically integrated model: from solar‑powered quarrying to final edge profiling, every stage is optimised for resource efficiency and client assurance.

As 2025 projects pivot toward wellness‑oriented spaces and carbon‑aware procurement, Grey Marble Slabs provide a resilient canvas—serene enough for meditation studios, robust enough for high‑traffic transit hubs, and luxurious enough for couture boutiques. Their understated elegance transcends fashion cycles, allowing architects to future‑proof interiors while meeting today’s sustainability mandates. Partner with Forustone, and transform grey from a mere neutral into a signature statement that endures for decades.