The New Era of Marble Slabs

Few building materials marry luxury, longevity and cultural heritage as effortlessly as Marble Slabs. From Greco‑Roman monuments to modern boutique hotels, their luminous surfaces turn ordinary interiors into timeless statements.

Yet the classic appeal of Marble Slabs is now shaped by 21st‑century forces: stricter sustainability regulations, worker‑safety rules, carbon‑pricing schemes and digital traceability requirements. Knowing how these “real‑time” policies interact with sourcing, fabrication, logistics and design is essential for architects, distributors and homeowners alike.

At forustone, we quarry, cut and finish premium Marble Slabs in a way that balances artistry with compliance. This 2 500‑word guide decodes the latest international frameworks—while offering practical tips on colours, finishes and installations that elevate kitchens, baths and commercial spaces worldwide.

Global Sustainability Policies Reshaping Marble Supply

The European Union continues to set the policy pace for construction materials. Three initiatives stand out for 2025 – 2027:

Digital Product Passport (DPP). Starting its phased roll‑out in 2024, the DPP requires each construction product sold in the EU (including natural stone) to carry a scannable dataset detailing origin, embodied carbon, quarry practices and end‑of‑life options. Suppliers unable to provide life‑cycle transparency risk losing market access.

Construction Products Regulation (CPR) 2.0. Revisions approved in 2024 strengthen environmental thresholds alongside traditional safety metrics. Life‑cycle assessments (LCA), recycled‑content targets and product‑specific EPDs (Environmental Product Declarations) are becoming compulsory tender documents for public projects.

Carbon Border Adjustment Mechanism (CBAM). Although marble is not in the first wave of iron, cement and aluminum, importers must still track embedded emissions. If stone is cut or polished in regions with higher carbon intensity, buyers could soon face levy extensions planned for 2026‑27.

For Asia‑Pacific and Middle‑East exports, Japan’s 2024 tariff table shows Marble Slabs entering duty‑free under HS 6802.91, but that same zero‑tariff status is conditional on new “green‑logistics” documentation from 2025 onward.

Worker‑Safety & Silica Standards in Stone Fabrication

Beyond carbon, global regulators are zeroing in on crystalline‑silica dust generated when cutting dense calcite or dolomite. Key developments include:

OSHA Silica Enforcement Initiative (US). Expanded in late 2023, it prioritizes inspections of cut‑stone plants and tightens exposure limits for respirable particles. forustone’s North American partners now install wet‑saw containment booths and real‑time air monitors as standard practice.

California Permanent Silica Standard (2025). The world’s first state‑level rule tailored to artificial and natural stone fabrication imposes mandatory medical surveillance and vacuum‑extraction tooling for any shop handling Marble Slabs over 10 % crystalline silica.

MSHA Final Rule for Miners (2024). Quarries supplying raw marble must meet a new 50 µg/m³ time‑weighted limit, influencing quarry‑ventilation design and shift rotations.

Collectively, these rules push the entire supply chain toward wet‑polishing lines, automated bridge saws with HEPA filtration and dust‑capture water walls—investments that raise safety while adding marginal cost. forustone’s in‑house testing lab certifies each batch to verify compliance before export.

Traceability & the Circular‑Economy Mandate

Sustainability frameworks such as the EU’s Level(s) and UK Green‑Paper reforms call for stone suppliers to demonstrate circular practices. Buyers of Marble Slabs now ask:

Can the quarry provide restoration plans and water‑recycling records?

Is transport optimized to cut empty‑container mileage?

Will slabs be accepted back for repolishing or down‑cycling into mosaics?

forustone addresses these points through:

Embedded RFID tags that sync with future Digital Product Passports.

Closed‑loop slurry filtration, reducing fresh‑water use by 73 % per tonne since 2021.

An “End‑of‑Life Buy‑Back” voucher on select coloured Marble Slabs—ideal for boutique hotels undergoing refurbishments where off‑cuts can be resawn into décor panels.

Choosing Marble Slabs for Design & Performance

Sustainability might secure project approvals, but aesthetics still seal the deal. Here are the dominant style directions for 2025:

Warm Minimalism

Creamy Bianco Perlino and soft‑veined Crema Marfil complement Scandinavian interiors, while meeting bright‑reflection requirements in WELL‑certified offices.

High‑Contrast Dramatic

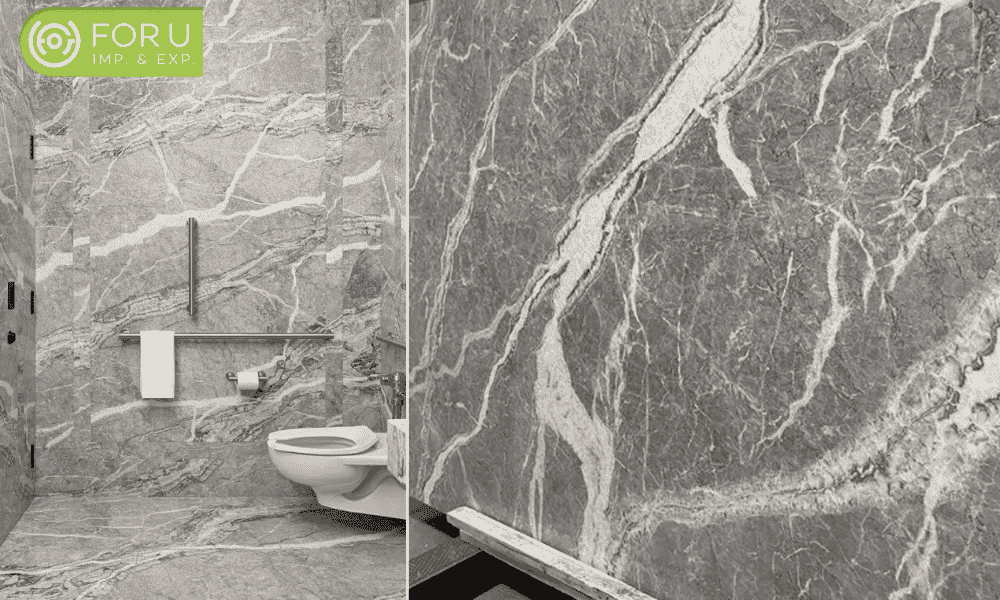

Monochrome Grolla Black or Paonazzo Gold‑vein Marble Slabs create bold focal points in hospitality lobbies. A honed finish under matte lighting keeps glare low yet accentuates dramatic veining.

Earth‑Tone Revival

Green Verde Ming and honey‑tone Rosa Levante speak to biophilic design, pairing stone authenticity with natural‑wood cabinetry.

Ultra‑Thin Mechanical Panels

For ventilated façades, forustone now slices certain Marble Slabs to 12 mm, bonding them to aluminium honeycomb for seismic stability while slashing cladding weight by 70 %.

Finish Innovations & Indoor‑Air Quality

Advances in CNC texturing allow leathered, sand‑tight or micro‑fluted surfaces that showcase depth while dispersing glare. forustone seals each finish with low‑VOC, food‑safe fluoropolymer impregnators—helping projects meet LEED v5 and BREEAM IAQ benchmarks.

Logistics, Tariffs & Documentation in a Post‑Pandemic World

Multi‑Modal Shipping. To reduce Scope 3 emissions and CBAM surcharges, we combine rail‑sea routes from quarry to port, generating 28 % less CO₂ than pure road+sea.

HS Code Clarity. Properly classifying Marble Slabs under 6802.91 (worked marble) versus 2515.12 (merely sawn blocks) can prevent 5–8 % duty disputes in ASEAN markets.

Insurance & Breakage. Insist on “all‑risk” policies covering edge‑chipping; with inflation, a single 2 × 3 m Calacatta book‑match can exceed US $10 000 replacement cost.

Why forustone Is Your Policy‑Ready Partner

Policy Scouting. A dedicated compliance desk tracks EU CPR updates, CBAM timelines and OSHA bulletins in real time.

Certifications. ISO 14001, ISO 45001 and CE under EN 1469 ensure that our Marble Slabs arrive with declarations ready for public‑tender portals.

Design Lab. Architects can request digital twins (IFC/REVIT families) embedded with EPD and DPP datasets—accelerating BIM workflows.

After‑Sale Stewardship. Our marble‑care kits feature neutral‑pH cleaners and micro‑crystalline waxes, minimizing the need for harsh chemicals that could violate local wastewater ordinances.

Breccia Violetta Marble-FOR U STONE

The journey of a Marble Slab from mountain to masterpiece is more complex—and more rewarding—than ever before. Modern policies challenge quarry operators to cut carbon, compel fabricators to banish respirable silica, and require importers to provide cradle‑to‑grave transparency. Far from obstacles, these mandates create a framework for excellence: stone that is safer for workers, kinder to the planet and demonstrably durable for generations.

forustone embraces this paradigm. By aligning our quarries and workshops with Digital Product Passport roll‑outs, CBAM‑ready carbon reporting and OSHA‑level safety controls, we help designers translate regulatory checklists into compelling architecture.

Our customers—be they luxury‑villa builders in Dubai, boutique‑hotel renovators in Paris or multifamily‑housing developers in Toronto—gain more than beautiful surfaces. They gain confidence that their Marble Slabs have been responsibly quarried, precisely cut and expertly finished under a regime of continuous improvement.

Looking forward, we see the role of Marble Slabs expanding beyond countertops and flooring. As 2025 unfolds, forustone stands ready to collaborate—merging time‑honoured craftsmanship with data‑driven accountability. Reach out with your CAD drawings, mood boards or sustainability targets, and our team will craft a tailor‑made stone solution that feels as good as it looks. Together, we’ll transform the built environment one iconic slab at a time.