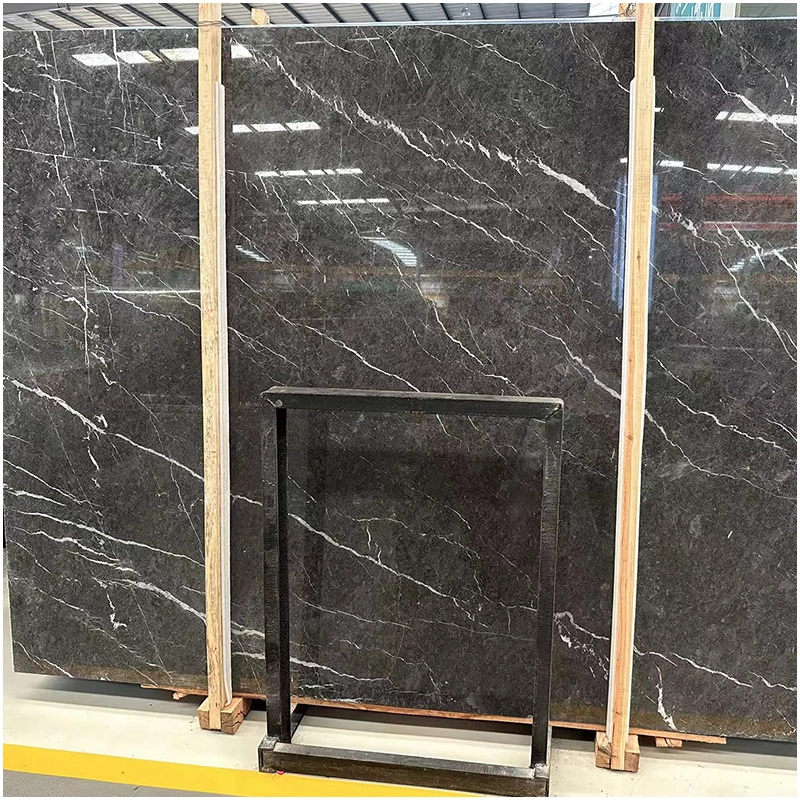

The Aesthetics and Craftsmanship of Gray Porcelain Slabs

Long a mainstay of architecture and interior design, porcelain slabs offers both beauty and utility. Gray porcelain slabs are somewhat common among the several kinds of porcelain slabs since they are modern and flexible. several homeowners and designers choose them because they mix perfectly with several design philosophies, from modern to traditional. Anyone wishing to include gray porcelain slabs into a place must first understand their manufacture, cutting, cleaning, grouting, and installation techniques.

What is Porcelain Slabs?

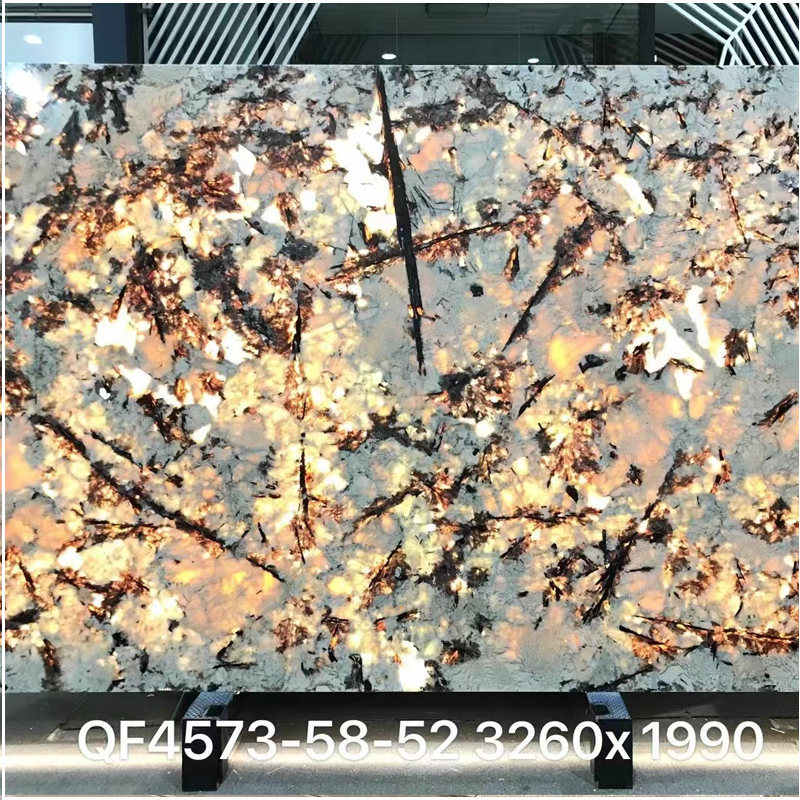

Covering surfaces like counters, walls, and floors, porcelain slabs is a flat, thin layer of material. They are constructed from ceramic, porcelain, natural stone, glass, and metal among other elements. Every kind of porcelain slabs has special qualities and advantages appropriate for diverse uses and aesthetic tastes. The most often occurring varieties are ceramic and porcelain porcelain slabs. Made from clay burned at high temperatures, they produce a hard, robust result. Perfect for kitchens and bathrooms, ceramic porcelain slabs is denser and less porous than other porcelain slabs, thereby providing great resistance to moisture and stains.

Made from big slabs of stone, natural stone porcelain slabs— Marble, granite, slate—have distinctive patterns and textures that cannot be duplicated with man-made porcelain slabs. These porcelain slabs opulence and durability make them common in high-end projects. Backdrops and decorative elements often feature glass porcelain slabs because of its vivid hues and light-reflecting properties. Though less prevalent, metal porcelain slabs is typically utilized in kitchens and businesses and gives any space a modern, industrial air. Porcelain slabs great range of sizes, forms, and colors opens countless design opportunities. Herringbone, basket weave, and mosaic are just a few of the ways they could be laid to provide visually appealing and distinctive surfaces.

Apart from their aesthetics, porcelain slabs are prized for their usefulness. They can withstand strong foot traffic and wear and tear, resist stains and dampness, and are simple to maintain. For places like kitchens, bathrooms, and doorways where longevity and cleanliness are critical factors, these features make porcelain slabs perfect. Porcelain Slabs are a must-have in both domestic and business environments since they provide a flexible and strong solution for a variety of uses whether utilized for ornamental elements or for utilitarian ones.

Gray Porcelain Slabs Production Method

To get the intended tone and impact from gray porcelain slabs, the manufacturing process calls for a mix of natural materials, precise machinery, and sophisticated technologies. The procedure starts with choosing raw materials, usually clay, feldspar, quartz, and other mineral pigments to get the gray hue. These well chosen components are then combined to create a homogeneous mixture. The combination is processed to produce a fine powder next. Water is mixed with this fine powder to create a slurry; this slurry is then further refined to guarantee the right consistency and eliminate any contaminants. The slurry is put into molds that decide porcelain slabs size and form once it is ready. These molds then dry to eliminate extra moisture, therefore helping to prevent any cracking or deformation during the fire process that follows.

The porcelain slabs are burned in a kiln in temperatures ranging from 1,000 to 1,250 degrees Celsius following the drying cycle. By fusing the particles in the porcelain slabs together, this firing process—known as sintering—results in a hard and robust output. Careful choosing and proportioning of mineral pigments added to the mix before firing results in the gray hue of the porcelain slabs. Sometimes a second fire is carried out following glaze application to improve porcelain slabs look and offer further stain and moisture resistance. Applying a layer of liquid glass to the porcelain slabs surface results in a smooth and lustrous surface that fuses with the porcelain slabs during the second burning operation. Every porcelain slabs is lastly carefully inspected for quality to make sure it satisfies the needed criteria. Only porcelain slabs that pass this test are ready for usage in many building and restoration projects and packed and ready for sale.

How are gray porcelain slabs made?

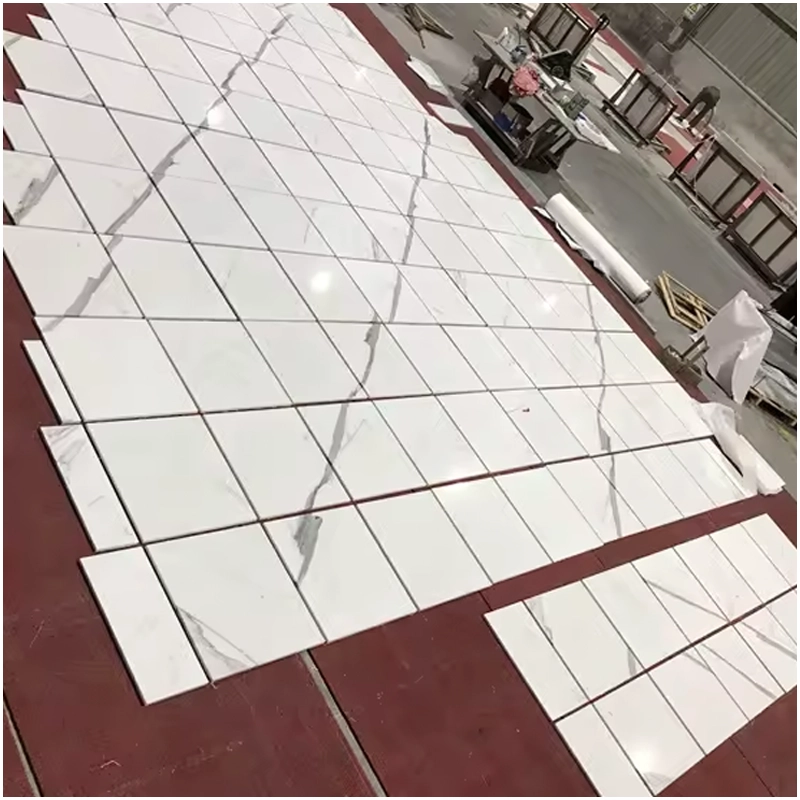

Cutting gray porcelain slabs is the same as cutting any other kind of porcelain slabs; it calls for accuracy and the correct tools to produce a neat and exact cut. Measuring the space where the porcelain slabs will be placed comes first; next, using a pencil or felt-tip marker, mark the porcelain slabs appropriately. This guarantees that the porcelain slabs fits exactly in its allocated spot and that the cut is made in the right place. After marked, set the porcelain slabs on a level surface and guide the cut with a straightedge. Often the equipment of choice for straight cuts is a manual porcelain slabs cutter. Along the designated line, this cutter’s carbide scoring wheel marks the porcelain slabs surface. The porcelain slabs is broken along the line with the break knife on the cutter following scoring, therefore enabling a neat cut.

A wet saw is usually used for more difficult cuts, like angles or curves, which need for Designed with a diamond blade and a water cooling system to enable exact cuts and minimize dust and porcelain slabs overheating prevention, a wet saw is a power tool. Placed on the sliding table of a wet saw, gently lower the blade onto the porcelain slabs to create the cut. Safety throughout the cutting process depends on wearing gloves, goggles, gloves, and earmuffs among other protective gear. Avoiding chipping or cracking the porcelain slabs depends on working slowly and precisely. Cutting gray porcelain slabs can be a straightforward operation with the correct tools and methods, so guaranteeing a professional appearance for any porcelain slabs job.

Gray porcelain slabs Cleaning Techniques

Maintaining the look of gray porcelain slabs and extending its life depend on its being cleaned. Porcelain slabs can get stains, filth, and grime with time, which would degrade their appearance. Regular cleaning guarantees your porcelain slabs is hygienic and helps it to appear best. Cleaning gray porcelain slabs starts with surface sweep or vacuuming to gather loose dirt and trash. This stops dirt from grind-through into the porcelain slabs during cleaning. Usually enough for regular cleaning is a light detergent combined with warm water. The porcelain slabs can be cleaned with this solution using a mop or soft cloth; then, to eliminate any soap residue, rinse it with pure water. Using abrasive cleansers or strong chemicals should be avoided since they could harm porcelain slabs surface and grout.

A stronger cleaning solution could be needed for more tough stains or excessively dirty surfaces. Many professional porcelain slabs cleaners on the market are designed especially to target difficult stains and debris. Always follow manufacturer directions when using these items to prevent porcelain slabs damage. Apart from routine maintenance, regular sealing of your porcelain slabs helps to guard them from stains and moisture. For porous porcelain slabs—like genuine stone, which absorbs liquids and gets dirty over time—this is particularly crucial. By building a protective layer from sealing your porcelain slabs, you may assist to maintain their appearance and simplify cleaning. Following these cleaning and care guidelines will help you to maintain your gray porcelain slabs looking fantastic and guarantee their lifetime of superb condition.

How to caulk gray porcelain slabs?

A crucial phase of the tiling process, cleaning gray porcelain slabs gives the finished appearance and keeps the porcelain slabs in place. The mixture of cement, water, and sand known as caulk fills in the spaces between porcelain slabs—that is, the joints. Gray porcelain slabs caulk calls for caulking, a caulking spatula, a sponge, and a pail of fresh water. Following manufacturer directions, the first step is to mix the caulk such that the texture is consistent and smooth. After the caulk is mixed, apply it to the porcelain slabs with a caulking spatula—a rubber tool used to evenly cover the porcelain slabs surface. Pressing the caulk into the joints with a trowel fully fills the joints and guarantees no air pockets or gaps.

Once the joints are filled, scrape any extra caulk from the porcelain slabs surface using the trowel’s edge. The caulk then sits for a few minutes, during which time it will start to solidify. Once the caulk starts to harden, clean any last bits off the porcelain slabs surface with a moist sponge. Continue this process numerous times, using fresh water each time, until the porcelain slabs is free of caulk residue. Before introducing the caulk to moisture or regular use, it should cure for at least 24 hours. Not only do properly caulked porcelain slabs look fantastic, but they also offer a watertight, robust surface capable of withstanding daily wear and tear.

How would one lay gray porcelain slabs on concrete?

Many building and restoration projects include laying porcelain slabs over concrete since it offers a strong and attractive surface for both indoor and outdoor spaces. Preparing the surface to guarantee it is clean, level and free of any cracks or flaws is the first stage in putting porcelain slabs on concrete. To clean the concrete or eliminate any high areas, this could call for using a concrete grinder or a pressure washer. After the surface is ready, run a notched trowel over the concrete applying a thin coating of mortar. The mortar bonds the porcelain slabs to the concrete acting as a bonding agent. Starting in the middle of the space and proceeding outwards to guarantee an even arrangement, the porcelain slabs are then set on the mortar. Firmly press each porcelain slabs into the mortar; then, apply spacers to preserve constant porcelain slabs gaps.

After the porcelain slabs are put, let the mortar set for at least twenty-four hours. After the mortar has cured, apply the same method before to grout the porcelain slabs joints. Before the porcelain slabs come into regular usage or dampness, let the grout cure for at least 24 hours. These guidelines will help you to accomplish a professional porcelain slabs installation on your concrete surface. Appropriately put porcelain slabs on concrete can create a long-lasting, robust and elegant surface resistant to a range of weather craffic.

Sand Selection for gray porcelain slabs Laying

A sturdy and durable installation depends critically on the kind of sand used when laying gray porcelain slabs. Usually combined with cement and water, sand is used to make mortar—a bonding agent that ties the porcelain slabs to the surface. Sharp, sometimes called coarse or rough sand, is the most often used sand for tiling. The angular granules of sharp sand offer great bonding qualities, which would help the porcelain slabs to have a solid and robust base. Avoid using soft sand, including building sand; this kind of sand has rounded particles and lacks the same stability, therefore producing a weak and unstable mortar.

Furthermore free of any contaminants, such clay, silt, and organic matter, which can compromise the mortar’s strength and longevity, should be the sand. To get the right consistency in the mortar, one need follow manufacturer directions. The mortar should be thick enough to hold the porcelain slabs in place but not too thick to make working difficult. Using the appropriate kind of sand and mixing the mortar properly will help you to guarantee that the porcelain slabs installation is robust and long-lasting. A professional-looking and long-lasting porcelain slabs job depends mostly on correct preparation and use of premium materials.

Gray porcelain slabs presents a classic and adaptable choice that may accentuate the usefulness and attractiveness of any area. Every element, from its exact production technique to the thorough stages of cutting, cleaning, grouting, and installation, contributes significantly to guarantee a high-quality output. Using the correct tools and supplies will help you to create a magnificent, long-lasting porcelain slabs installation. Whether you are a professional working on a new project or a homeowner wishing to remodel a room, knowing the nuances of using gray porcelain slabs will enable you to make a wise choice and get the best results. Gray porcelain slabs is still a popular choice for a beautiful, long-lasting surface when combined with utility.