Points to pay special attention to

1. Dry hanging stone should pay attention to the following aspects:

(1) Select stainless steel dry hanging pieces of qualified quality. The anti-rust function of unqualified dry hanging parts can not meet the requirements, and will rust during long-term use, thus polluting the hanging mouth.

(2) Choose oil-proof stone protective agent. When using it, check if there are oily separators in the dry hanging glue. When blending the adhesive, the two components A and B should be fully mixed to ensure crosslinking within the curing time, thereby reducing the infiltration of the glue monomer on the stone.

Because the glue monomer of the adhesive, if it is immersed in the stone hook when not cross-linked, it will exist for a long time between the crystals of the stone, and it will crosslink itself into a translucent solid, making the stone hook appear “crescent” or semi-circular Adhesive contamination. Fully reconcile the two components A and B to prevent the occurrence of adhesive contamination.

(3) After the stone dry hanging short slot is cut, it should be protected. Since the protective agent is generally completed in the factory, the short groove is cut after the scene and the original protective surface is damaged. Therefore, it is necessary to repaint the oil-proof antifouling agent. This type of antifouling agent can effectively prevent solvents and glues. The monomer infiltrates the stone to avoid pollution.

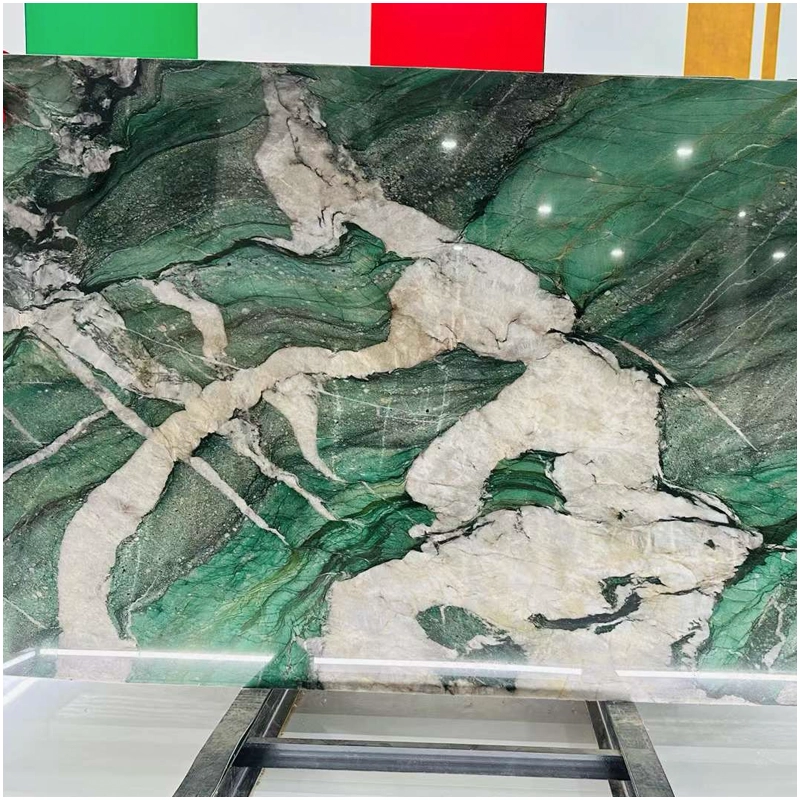

G603 G654