Natural stone common surface processing (Surface Finishing) method

The processing method of surface treatment of a wide variety of stone, such as bright surface, burning surface, litchi surface etc.. Different processing surfaces may be suitable for different places or different processing surfaces to cooperate with each other, which can enhance the effect of the building. The surface treatment of stone is one of the focal points that designers consider.

For European style villa stone wall, most of US adopted a fire surface treatment method, together with some of the polished surface, sub surface and other surface treatment methods.

The following are some commonly used stone surface treatment:

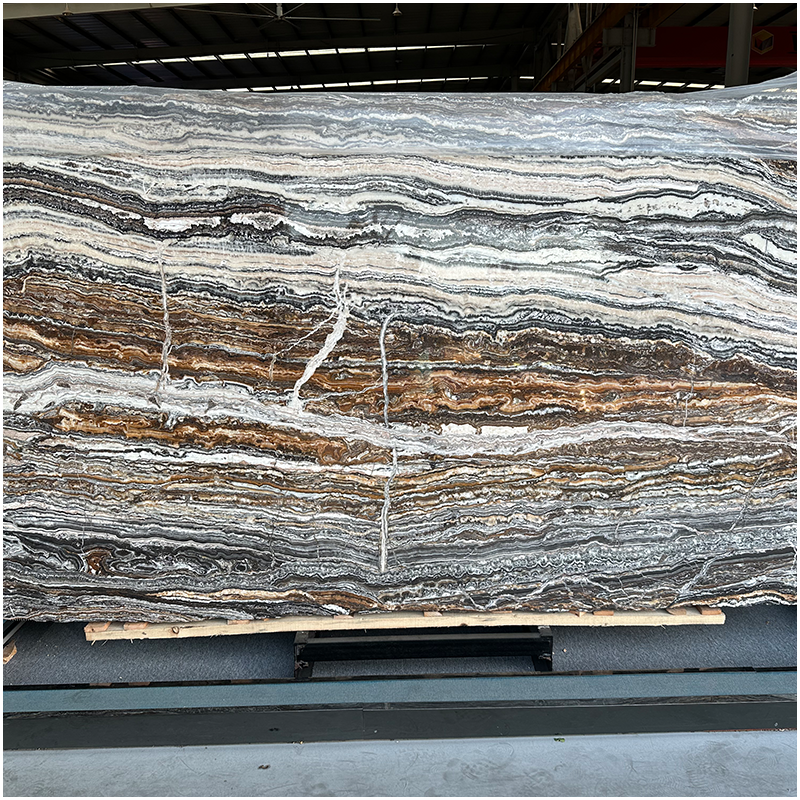

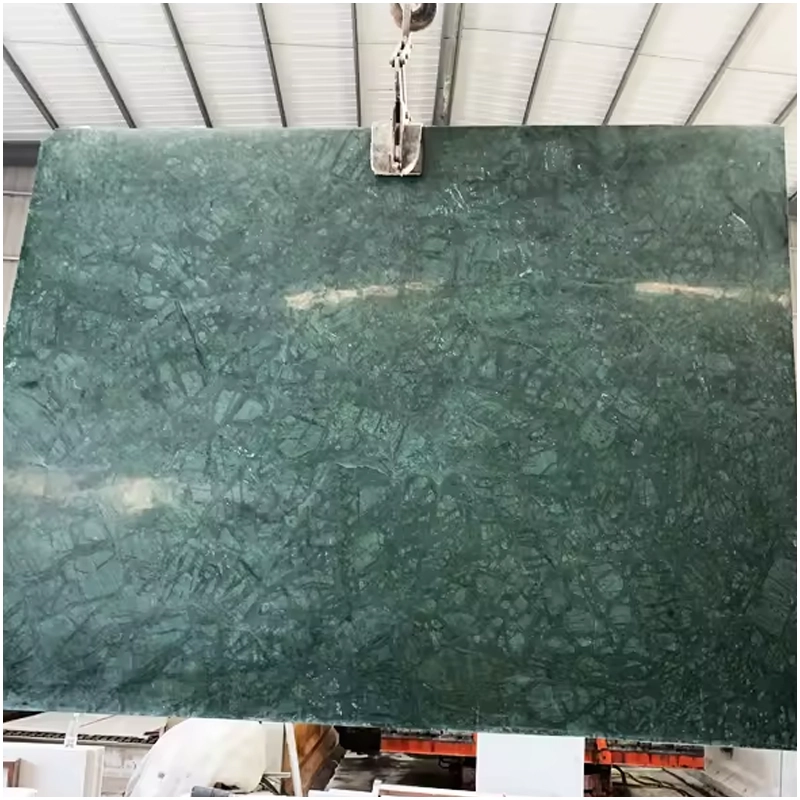

1, polished surface (surface polishing, polished):

Refers to the surface of the polished surface is smooth, with resin abrasive polishing etc. on the surface of the plate with specular gloss. General stone photometric can do 80, 90 degrees, and some stone species can even do more than 100 degrees, but some stone species can not be polished, the most can only do sub light. Generally speaking, the higher the brightness, the higher the price. The polished surface is generally used in flat curtain walls and indoor walls, floors, etc., especially some high-end buildings, the indoor wall and floor of the photometric requirements are high. The special film has high luminosity and strong reflection to the light, and can fully display the rich and colorful colors and natural textures of the stone itself.

2, Matt (honed):

Matt refers to a smooth surface, polishing processing less resin abrasive on the surface. Its brightness is lower than the grinding surface, generally in 30-50, 60 or so. Having a certain luminosity but weak in reflection of light. A sheet with a smooth, smooth surface and low luminosity.

3, burning face (singeing flamed):

Refers to the use of oxygen or acetylene, propane, oxygen, or liquefied petroleum gas, and oxygen as fuel to generate high temperature flame for processing stone surface rough surface. A small number of stone can not be processed by fire, or the effect of processing is not good. Because of the effect of burning, you can burn some impurities and low melting point of the stone surface, thus forming a rough finish on the surface, and touch it will have a certain sense of thorn. The processing of the fire surface has certain requirements for the thickness of the stone, in order to prevent the stone fracture during processing, the thickness is generally required to be at least 2CM, and some stone thickness requirements will be higher. In addition, there are some materials in the process of fire will be a certain color change, such as rust stone (G682), burning after the rust stone will show a certain pale red, rather than the original yellow rust color. The surface of the fire is characterized by rough surface, natural, non reflective, fast processing, relatively cheap price, often used for dry hanging on the exterior wall.

4, litchi surface (bush-hammered):

Litchi surface is shaped like a litchi peel and hammer on the stone surface, thereby forming a rough surface such as litchi peel on the stone surface, surface in carving surface or square stone etc.. The machine is divided into surface (machine) and Li Li face hand (hand) two, general hand machine more than Lai Lai fine, but time-consuming.

5, Logan surface (chiseled):

A hammer with rough surface Logan surface on the surface of the stone like appearance of eyelid forming staggered percussion, is one of the most common mode of granite sculpture surface processing, and is also divided into litchi surface, machine and manual two.

6, chop axe (Chiselled):

Also called longan, with ax chop knocking on the stone surface, forming a striped texture very dense, somewhat like the skin effect of longan.

7, pineapple (rough-picked):

Pineapple plate on the surface of the stone with a chisel and hammer on appearance like pineapple peel. Pineapple noodles than litchi noodles and longan noodles, but rough. It can be divided into two kinds: coarse pineapple noodles and thin pineapple noodles.

8, antique surface (flamed+brush):

In order to eliminate the surface characteristics of fire thorn in hand, in the stone first after the fire, and the steel brush 3-6 times, which is the antique face. The antique face has the concave and convex feeling of the burning face, feels smooth and can not prick hands, and is a very good surface treatment method. There are many methods of antique noodles, such as after burning water, acid corrosion, direct steel brush or high pressure water surface, and so on. Antique surface processing more time-consuming, at the same time, the price is more expensive.

9, Noodles with Mushroom Noodles (mushroom):

Noodles with Mushroom Noodles refers to the surface of the stone with a chisel and hammer on the sheet metal forming such as undulating gable. This method of processing has a certain requirement for the thickness of stone. Generally, the bottom thickness should be at least 3CM, and the convex part can be 2CM or more according to the actual requirements. Mushroom stones are heavily used in economical fences.

10, natural surface (naturalcleft):

Nature refers to hammer a piece of stone in the middle of natural split, forming processing method like natural rock extremely uneven surface. The natural surface is very rough, widely applied in small pieces, Luyandan products above.

11, tangent plane (Machine-Cut):

Directly by the circular saw sand saw or bridge cutting machine cutting and forming equipment, the surface is rough, with obvious machine cut lines.

12 ditch surface (Grooved):

Certain groove depth and width of the stone on the surface.

13, sandblasted (Sandblasted):

With ordinary river sand or sand surface diamond instead of high pressure water to flush the stone, forming a decorative surface grinding effect of the formation of sand.

14, the water surface (Water-jet):

With high pressure water directly impact the stone surface, peeling soft components, formed a unique

15, wash your face (Brushed):

Old surface. The process is to scrub the stone surface, mimicking the natural wear and tear of stones.

16, rolling surface (tumbled):

Surface smooth or slightly rough, smooth edges and is broken. There are several ways to achieve rollover effects. A 20 millimeter brick can tumble in a machine, and 3 cm bricks can be rolled over and split into two bricks. Marble and limestone are preferred materials for tumbling treatment.

17 (Nature Split), surface cracking:

Commonly known as natural surface, the surface roughness, but not as rough fire. This surface treatment is usually used in mine hand cut or crack chisel to expose the natural stone surface.

18 (Pickling), acid wash:

With acid corrosion of the stone surface, the small traces of corrosion, the appearance is more simple than the polished surface. Most stones can be pickled, but the most common are marble and limestone. Acid washing is also a way to soften the luster of granite